Mechanical Engineer

Shell

Eco-marathon

About Shell Eco-marathon:

Shell Eco-marathon is a global academic program focused on energy optimization and one of the world’s leading student engineering competitions. The Texas A&M Shell Eco-marathon team was formed in 2018 and it competes on the urban concept IC engine division. Due to a catastrophic rear axle failure in 2019 and Covid-19, the team has not been able to compete in person.

Problem Statement:

“The objective for TAMU’s SEM 2021-2022 season is to improve the design of the vehicle while completing general construction and maintenance to ensure the vehicle is able to compete in the 2022 Shell Eco-Marathon Competition.”

Needs Analysis:

In order to identify what the needs and requirements are for the competition, the team worked closely with shell representatives, analyzed each system, and most importantly, developed a House of Quality (HOQ) for each subsystem. The Body and Frame subsystem HOQ is shown on the right.

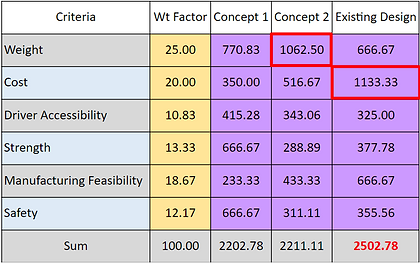

In order to create concepts, the team used different tools like TRIZ, patent research and morphological matrices. This last one was especially useful to create concepts with ideas of several team members simultenously. In order to decide final concepts, the team used an Independent, Intuitive, Averaged Evaluation (IIAE) matrix shown on the right

Idea Generation:

My Work on the Team:

Brakes & Steering Captain

I am managing a team of 5 members to optimize the brakes and steering subsystem. Specifically, we are relocating the steering components, the braking and acceleartion pedals, as well as redesigning the parking brake.

Steering Components Relocation:

Problem:

Previoulsy, the steering rack was mounted on a frame member that was located on the driver's knees. This was uncomfortable for the driver and affected the vehicle dynamics since it caused an asymetrical turning radius.

Concept:

The initial concept consisted of extending the steering column to the floor of the car. This meant that a new frame member would be necessary to mount the steering rack on the floor of the car.

Final design and manufacturing:

The steering column was extended using steel. The spline on the u joint was divided in two and the tube was fitted and welded between the separated splines. The clearance between the spline and the steering column was 0.05 inches which turned out perfect for the welding. This resulted in a more comfortable steering setup for the driver and a symmetrical turning radius.

Parking Brake Redesign:

Problem:

The parking brake that was mounted to the car was nonfunctional and inefficient. This was an independent braking system that added a separate set of braking calipers to the rear wheels, making it a heavy system.

Concept:

The new parking brake would use the car braking system and lock the brake pedal using a system of pulleys and cam-cleats. This was discussed with shell to make sure the design was legal for competition. This design would need mountings for the pulleys and the cam-cleats and a strong cord with which the driver can pull the braking pedal.

Final design and manufacturing:

The parking brake mounts were made of aluminum 6061 plate since it is cost efficient and sufficiently strong. The cord that is being used is professional Nylon cord used for fishing and the system is ready to be mounted on the car.

Pedal Relocation:

Problem:

The previous pedals were mounted on the lower frame member, causing discomfort to the driver due to the angle of approach between the driver's feet and the pedals which was not what automotive standards recommend. Also, the acceleration pedal was on the right side of the car and the braking pedal on the left side, which could be confusing for the driver.

Concept:

The pedals will be flipped and relocated on the upper frame member. This means that new mounts are necessary, but the pedals will be saved making this concept time and cost effective. The goal of this concept is that the driver can use his right foot comfortably to press both pedals.

Final design and manufacturing:

The mounts are currently being manufactured, and they will be made of 3/8 " aluminum 6061 plate. The ergonomics of the concept were verified by the prospective driver and were approved.